Capabilities

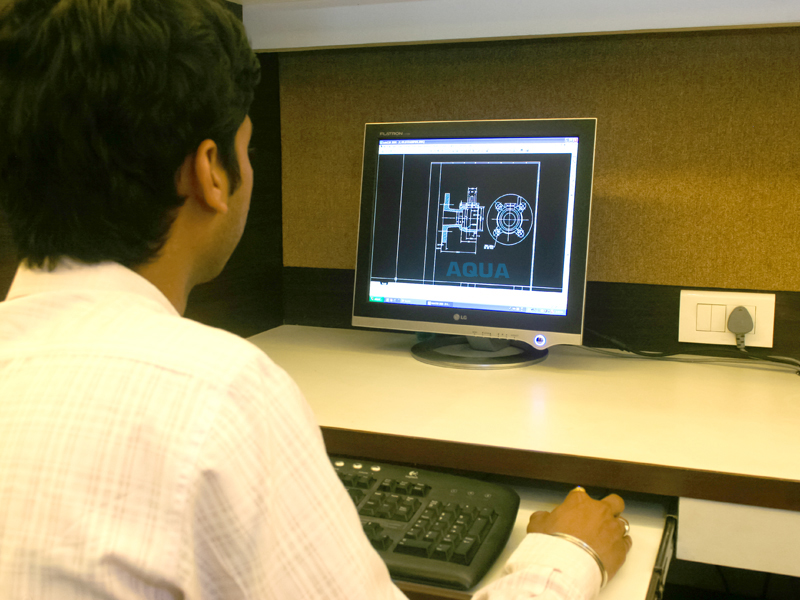

Design

All the products designed are tested with finite element procedure before they are released for production. Almost all the valves are designed to be manufactured in investment cast technology of radiographic quality. Every valve is designed to latest editions of International & National standards with respect to minimum wall thickness, mounting standards & material of construction.

Manufacturing

Manufacturing is carried out on modern CNC machines, tools of the latest technology are used, modular construction system is applied, ergonomic work station concepts for every sized valve, and online assembly & testing systems make our valves the best in its class when compared to any other leading brands in the world.

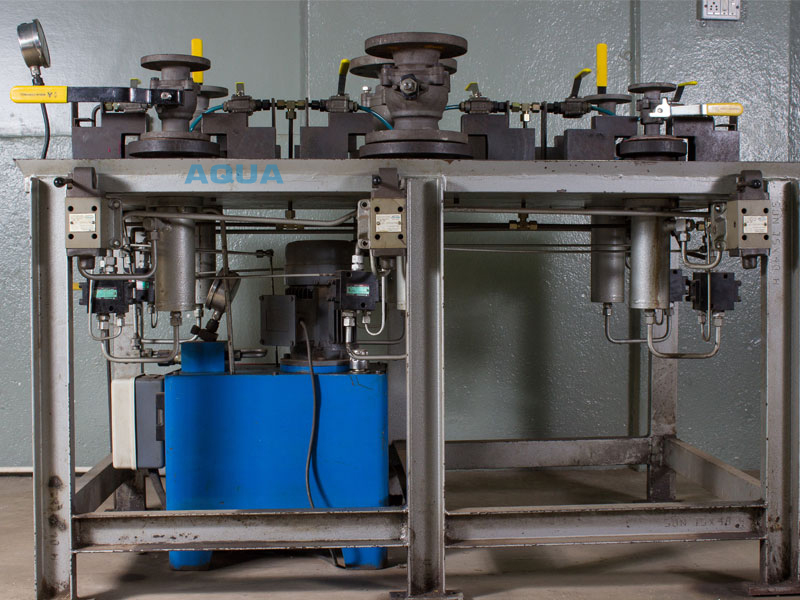

Testing

Equipped with modular & latest hydraulic independent testing benches, online size wise testing concept gives guarantee of the products to the customers. All the valves are finally tested according to the latest international standards.

We co-operate with any third party inspection agencies on the request of our valued customers.

Gallery Images

Products

- Ball Valves

- Flanged End, 2/3 Piece, Full Port, Class 150/300, Size 15-40

- Flanged End, 2 Piece, Full Port, Class 150/300, Size 50-200

- Flanged End, 2/3 Piece, Reduced Port, Class 150/300, Size 15-50

- Flanged End, 2 Piece, Reduced Port, Class 150/300, Size 65-250

- Screwed End, Socket Weld, Butt Weld, 3 Piece, Full Port, Class 800, Size15-50

- Screwed End, Socket Weld, Butt Weld, 3 Piece, Reduced Port, Class 800, Size 15-50

- Screwed End, Single Piece, Full Port, Class 150, Size 6-50

- Flanged End, Jacketed, Full Port, Class 150, Size 25/50 to 150/250

- Butterfly Valves

- Control Valves